1.AIM V9 FEATURES

*Low Voiding: as low as 1% on BGA and <5% on BTCs

*Capable of Consistent Printing with Area Ratio <0.66

*High Reliability (SIR)

*Drop-in for M8

*REACH and RoHS* Compliant

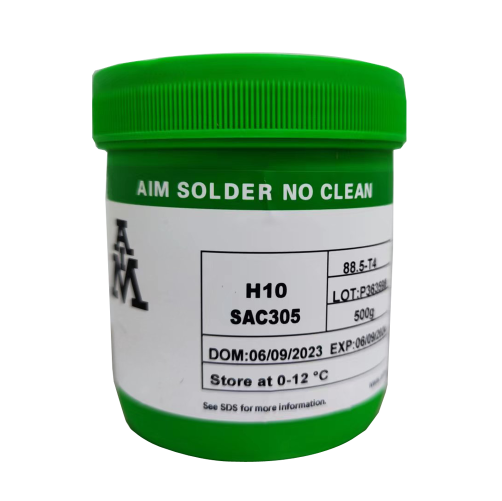

*Available in SAC305 T4

2.DESCRIPTION

AIM V9 No Clean solder paste is formulated for near-zero voiding on BGA, BTC and LED soldering applications. Significant void reduction achievable on all surface finishes including ENIG, ImSn and OSP. V9 exhibits stable print performance on fine feature devices over 12 hours. V9 post-process residue is easily pin-probed and has high SIR values.

3.CLEANING

Pre-Reflow: AIM DJAW-10 effectively removes V9 solder paste from stencils while in process. DJAW-10 can be hand applied or used in under stencil wipe equipment. DJAW-10 will not dry V9 and will enhance transfer properties. Do not over-apply DJAW-10. Do not apply DJAW-10 to stencil

topside. Isopropanol (IPA) is not recommended in process, but

may be used as a final stencil rinse. Post-Reflow Flux Residue:AIM V9 residues can remain on the assembly after reflow and do not require cleaning. Where

cleaning is mandated, AIM has worked closely with industry partners to ensure that V9 residues can be effectively removed with common defluxing agents. Contact AIM for cleaning compatibility information |